Biogas consists mainly of methane (CH4) and carbon dioxide (CO2). Methane is a valuable form of gas, as it is an efficient energy carrier with a wide range of uses. The amount of CO2 that is produced corresponds to the amount of CO2 captured when the biomass was created.

This means that biogas is a CO2 neutral and renewable source of energy.

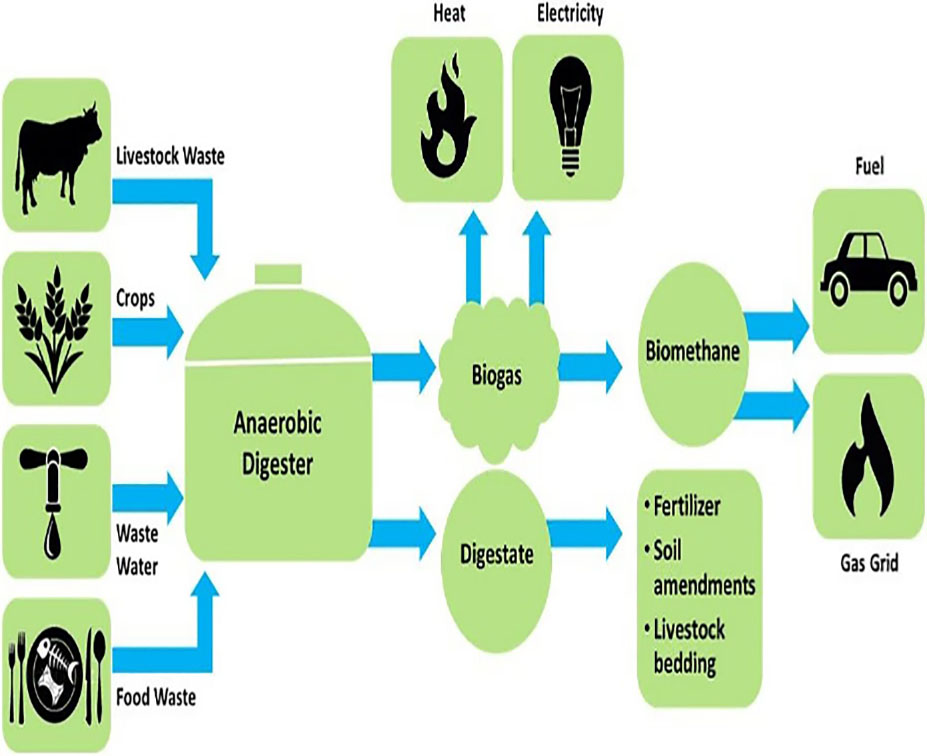

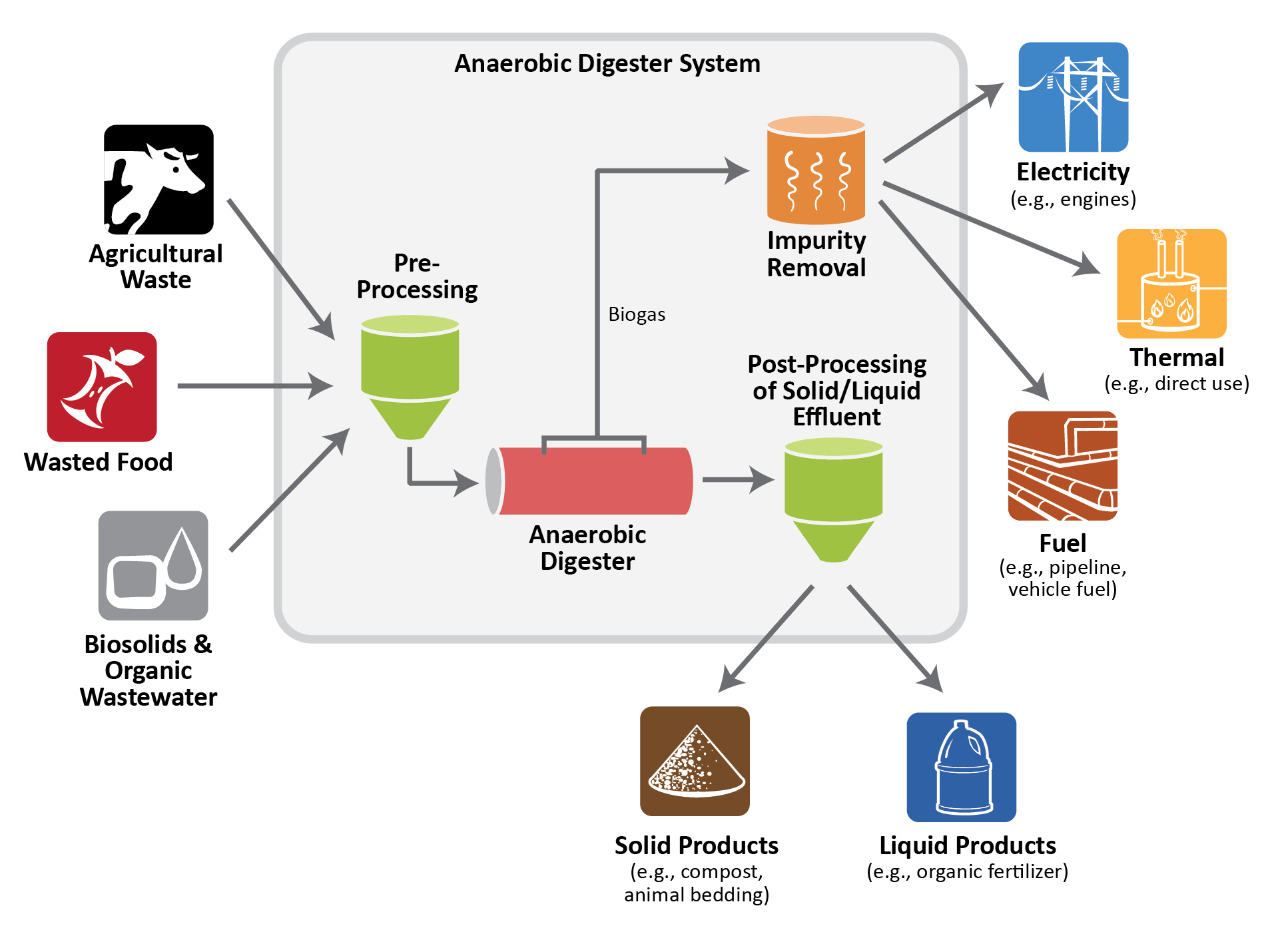

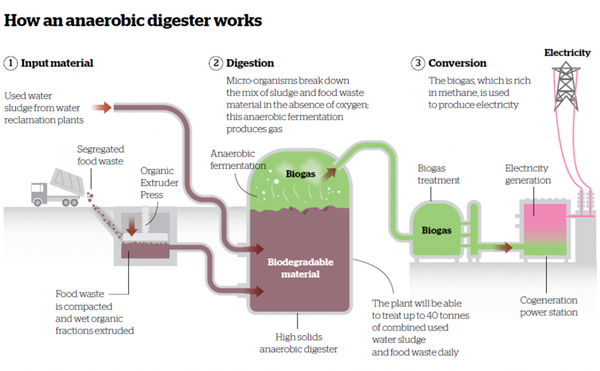

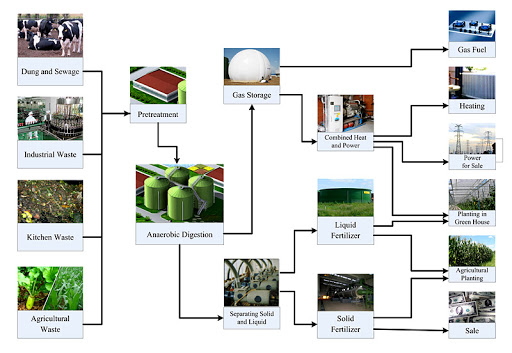

Biogas is produced using organic material, which is broken down with the help of bacteria in an anaerobic (oxygen-free) environment. The anaerobic digestion process is a natural process that often occurs in nature. In a biogas plant, this process takes place in an anaerobic digester and is accelerated by creating the best possible conditions for micro-organisms and bacteria to multiply, which leads to a highly efficient breakdown of materials. Almost all forms of organic material can be used to produce biogas. However, waste water, manure, energy crops and organic industrial waste are the most common feed stocks.

Anaerobic digestion is a biological process making it possible to degrade organic matter by producing biogas which is a renewable energy source and a sludge used as fertilizer.

The production of biogas is carried out in the environment in a natural way (e.g. gas of marshes - vegetable and animal matter decomposition where the formation of bubbles at water surface can be observed).

In the absence of oxygen (anaerobic digestion), the organic matter is degraded partially by the combined action of several types of micro-organisms. A succession of biological reactions (see diagram) led to the formation of biogas and sludge.

The bacteria which carry out these reactions exist in natural state in the liquid manure and the anaerobic ecosystems; it is not necessary to add more, they develop naturally in a medium without oxygen.

A biogas plant is the name often given to an anaerobic digester that treats farm wastes or energy crops. It can be produced using anaerobic digesters (air-tight tanks with different configurations). These plants can be fed with energy crops such as maize silage or biodegradable wastes including sewage sludge and food waste. During the process, the micro-organisms transform biomass waste into biogas (mainly methane and carbon dioxide) and digestate.

Optimising the power supply of the digester

Several types of waste

Regular quantity of waste

Measure the intermediaries of reaction

To take care of the good nutritional balance - balances between carbon, nitrogen and phosphorus

Types of organic matter to be targeted - all except lignin and cellulose

Bio Energy Independence and degradable waste management for schools and colleges, Hospitals, corporations, Panchayat, industries, marriage halls, and other public gathering places.

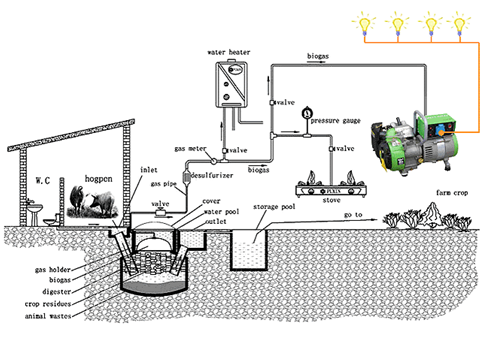

Biogas is made in a biogas digester. We call it a digester because it is a large tank filled with bacteria that eats (or digests) organic waste and gives a flammable gas, called biogas. The bacteria in the biogas digester need to be cared for like you would care for an animal. If the bacteria have too much or too little food they get sick. You must feed the bacteria every day with a mixture of food waste and water. In addition to biogas, the systems make waste water that is rich in nutrients. This water may be poured over your plants to help them grow.

Biogas systems make use of a relatively simple, well-known, and mature technology. The main part of a biogas system is a large tank, or digester. Inside this tank, bacteria convert organic waste into methane gas through the process of anaerobic digestion. Each day, the operator of a biogas system feeds the digester with household by-products such as market waste, kitchen waste, and manure from livestock. The methane gas produced inside biogas system may be used for cooking, lighting, and other energy needs. Waste that has been fully digested exits the biogas system in the form of organic fertiliser.

Biogas can be compressed, the same way as natural gas is compressed to CNG, and used to power motor vehicles. In all countries, for example, biogas is estimated to have the potential to replace around 17% of vehicle fuel. It qualifies for renewable energy subsidies in some parts of the world. Biogas can be cleaned and upgraded to natural gas standards, when it becomes bio-methane. Biogas is considered to be a renewable resource because its production-and-use cycle is continuous, and it generates no net carbon dioxide. As the organic material grows, it is converted and used. It then regrows in a continually repeating cycle. From a carbon perspective, as much carbon dioxide is absorbed from the atmosphere in the growth of the primary bio-resource as is released, when the material is ultimately converted to energy.

Maintenance and management

To supervise the food of the digester constantly

Not to neglect the maintenance of the digesters

Bio Energy is the Energy obtained as a part of degradable waste treatment system, assisting in the “Reduce, Reuse, Recycle” approach to lessening the pollution load we currently place on our planet.

What are degradable waste available?

Kitchen waste — obtained during food preparation.

Food waste — obtained,

Wash water — kitchen

Garden waste — trimming

Waste paper pulp — company

Human waste — human

Ways of obtaining Bio —Energy

Bio energy is obtained in the form of Bio Gas as a by-product during the anaerobic digestion which takes place inside the anaerobic digester with the help of various kind of anaerobic bacteria's on the degradable waste. It has been calculated that 8532 MW per day of energy can be obtained by proper use of available degradable waste.

How Bio gas useful for us

Bio gas is the best source of renewable energy which can be used for wide application directly for cooking / heating lighting, adsorption refrigeration, gas engine and generating electricity.

Bio gas can be used as bio fuel for various application from cooking heating drying and lighting the bio gas is mixing with air at proper ratio and get burned is burner where we can convert the useful energy to a desire work done .

Bio Gas can be used for refrigeration with the help of Vapour Adsorption Machine (VAM)

1000 m3 of Raw Bio gas replaces 27 LPG (14.5kg) Cylinder

Electricity can be generated from Bio Gas using Gas engine or fuel gas engine. The electricity generated is clean and have lesser environmental act than other Fossil fuels with co-generation of Hot water & adsorption using CHP Overall efficiency of the system can be increased.

For 400 m3 we can run 62.5 KVA Genset for 8 Hours Continuously

For 1000 m3 we can run 125 KVA Genset for 8 Hours Continuously

For 2000 m3 we can run 250 KVA Genset for 8 Hours Continuously

One kg (1 kg) pure Bio Methane can give 22-24 km for a passenger car with dual fuel bio methane kit for bus, the bus can run at 25% diesel and 75% bio methane and overall KMPL is 16.

Bio Gas can be used as vehicle fuel by using CNG kit. The CNG System improves the methane percentage of Bio Gas from 60% to greater than 95% and then with help of CNG compressor it is filled in CNG tank of a vehicle.

In particular now the vehicle is called as natural gas vehicle (NGV), contributing to conservation of petroleum and reducing pollution compared to Petrol & Diesel.

NGV produces less - Nitric Oxide (NO) family gas, Carbon Monoxide (CO) by 30% — 50%, (CO2) by 20% — 30% and produces no SO family gas. Also the Octane number of Bio Methane is 130, which is far higher than Petrol (Octane No.96) reducing fuel consumption with improved engine compression ratio and mileage.

One kg (1 kg) pure Bio Methane can give 22-24 km for a passenger car with dual fuel bio methane kit for bus, the bus can run at 25% diesel and 75% bio methane and overall KMPL is 16.

The use of Bio Gas can be enhanced further by bottling the gas and dispensing at various point of use. The bottling of Bio Gas can be done with a proper Bio G consists of Bio Gas enricher. Bio dispensing arrangements. With this for large Volume of anaerobic digester which improves the reliability of total available bio energy.

For 1000m3 raw Bio Gas minimum 400 kg of pure bio methane is obtained for bottling, which is equal to 27 LPG (14.5kg) cylinders.

To take into account the entire investments

Three principal sources of revenue: sale of electricity, developed heat and service of organic waste elimination

A good electricity valorisation

1 m3 of biogas is equivalent to close to 0.5kgs of LPG. The biogas can be used as replacement for LPG in cooking. 1 m3 of biogas is equivalent to approximately 1.5 KW of power if the power generation. Bio gas can also be further purified for generating BIO-CNG. Bio-CNG can be used as replacement for LPG. Natural gas cooking applications. Bio-CNG can also use a vehicle fuel. Biogas is the only fuel which can be used in different forms unlike other renewable energy sources

Biogas is an important renewable energy resource for rural area in India.

It is produced by anaerobic digestion of biological wastes.

It is an environment friendly, clean, and versatile fuel.

Biogas generally comprise of 55-65% methane 35-45%

Carbon dioxide, 0.5- 1.0 % hydrogen sulphide and traces of water vapour.

Average calorific value is 20MJ/m3 (4713 kcal/m3)

Biogas technology offers a vast set of benefits. It is a viable technology for all areas and away from the low cost power generation utilities. However there is not much raw material to meet the huge demands.