Quantic Edges Storage Solutions designs, supplies and installs warehouse storage solutions to meet your requirements. We are your warehouse equipment supplier serving Pan India both new racking equipment and used pallet rack, giving you the choice to meet your racking budget. We design, supply and install mezzanine, archive/record storage, pallet rack, push back rack, pick modules, carton flow rack, cantilever racking, drive-in racking, wire mesh decks, pallet rack shelving, marine storage systems, garment rack, gravity roller conveyor, material handling equipment, and slotted angle.

We welcome equipment and can relocate or dismantle warehouses at short time. Our professional team is skilled to ensure that the right pallet rack solution is designed to fit your warehouse space. Working with clients for over 15 years, we recognize that deadlines and budgets are extremely important and that's where Concept Storage Solutions scores high with every installation. At Concept, we focus on doing the job right to earn an on-going relationship with our clients. If you are moving into a new location or just improving your present facilities, Concept Storage Solutions will design and develop the solution that’s best for your storage facility. We service all kinds of industries and institutions and offer free consulting with CAD drawings.

Quantic Edges Storage Solutions, we provide quality pallet rack products and services to our client base. Our professional staff and our ability to build trusting relationships are the reason why we've consistently earned the business of many Top Fortune 1000 companies. At Concept Storage Solutions,

We used the latest AutoCAD software to design storage solutions for our customers.

As part of our service, we provide:

Final detailed plans and elevations required to establish storage yields for customer inventory control

In-house prototype testing at our facility for Pallet flow systems

Certified engineering drawings for building permits, if required

Fabrication drawings required for production

AutoCAD software is only as good as the designers using it. Our design team is comprised of four professionals who are specialists in structural engineering and architectural design. This team has over 25 years' combined experience designing cost effective storage solutions all over India

With a well-designed racking system, you can improve warehouse productivity, increase storage space by 40% or more depending on the warehouse design. Choosing the right pallet racking system can make a big difference in your business outcomes. The main step is to decide what type of pallet rack suits best for your business requirements

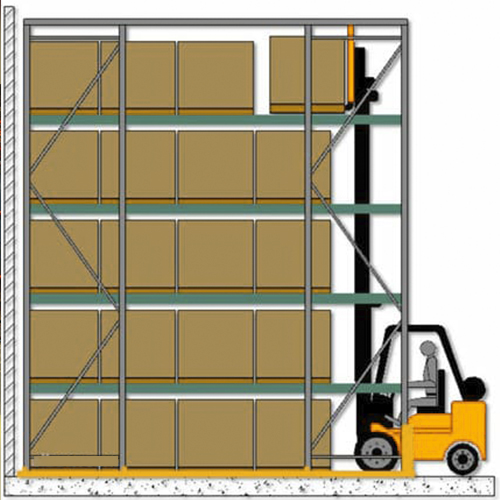

Selective pallet rack is the most common and flexible pallet racking system in the industry. It provides efficient use of storage space and quick access to every load stored using any type of forklift. This type of rack is available in debris-resistant, easy-to-clean structural steel (ideal for food handling operations). The selective pallet rack is used commonly in manufacturing, retail, and general warehousing.

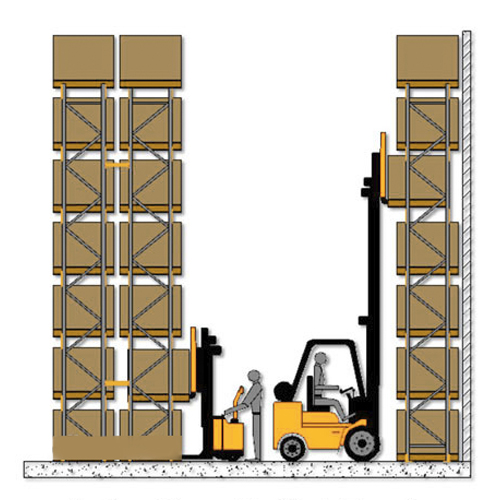

Double-deep racks are made by placing one row of selective racking behind another. This is the most affordable way to create high-density storage in the warehouse. Double deep racking can increase storage for up to 40% depending on the warehouse structure. It is recommended for general warehousing and manufacturing business.

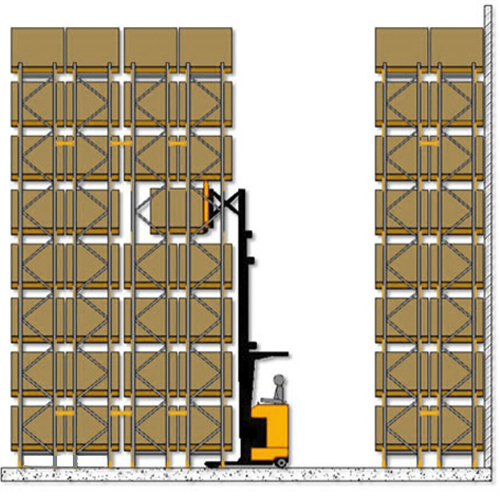

Drive-in pallet racking system follows last-in/first-out rotation. It is designed to increase the utilization of floor space within a warehouse. This type of racking system requires a small passage area for the same amount of storage thus saving storage space. It is designed in a way that allows forklifts to make their way through the aisles to continue stocking and adding more pallets. It is suitable for large-volume storage of similar products, general warehousing, freezer, and high-turnover retail products

These pallet racking systems have a last-in/first-out (LIFO)) rotation and are fabricated in structural or roll form. These systems are suitable for high-density multiple product storage. Push back racking allows easy access to inventory items and also good for a specific selection of inventory items. When a pallet is loaded or placed on the structure, the next pallet is pushed backward on the rails where it rests firmly. When the pallet is unloaded, they are ‘pushed’ to the front of the structure. Therefore it is called push back rack or back rack system. It is generally used in food-oriented operations, general warehousing, and retail.

A mezzanine floor is an intermediate floor which is built between two main floors or the floor and ceiling of a building. They are designed to cover a specific area of a building rather than extending over the entire floor space. Mezzanines are installed to maximise unused vertical space, providing additional room above and below and can be built free of existing structures. Industrial settings are some of the most common places a mezzanine is built due to their high-ceilings and are usually free-standing, semi-permanent structures. Mezzanines are often custom-made, manufactured from detailed drawings and tailored to the needs and specifications of a client. Typically, mezzanines are constructed from steel and can be tailored to suit their settings.

Pallet flow rack, also called gravity flow racks, utilize sloping racks. In pallet flow rack, new pallets are added at the higher end and removed from the lower end, thus it is a first-in/first-out (FIFO) loading system. Pallet flow storage can double or triple storage capacity as compared to drive-in or conventional pallet rack systems and is a perfect solution for freezer warehouses, food distribution centres, and storage of high-volume, perishable consumer goods.

Cantilever racking is ideal for storing long products such as textiles piping, tubing tires, furniture, carpet rolls, steel rods, and timber. The racking structure has long arms extended from a metal framework specifically designed to store long and heavy items. Cantilever racking allows easy access to all the inventory items as it has no front column, unlike other pallet racking systems.

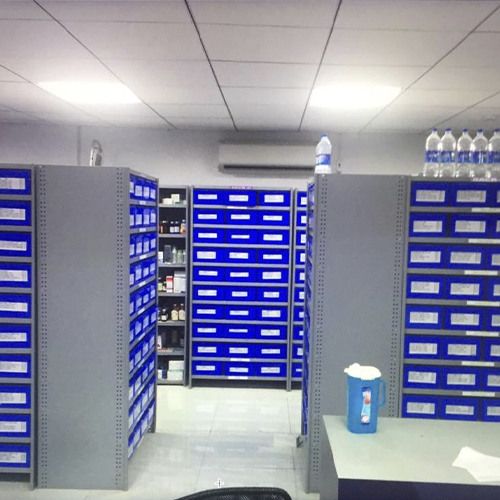

Our System is a new age space saving concept and has been widely accepted across the various industrial verticals and in Hospital & Pharmacies, Pharmaceutical distribution centres & Related E-commerce application Industries.

a) 1275 MM (4 FT)

b) 1875 MM (6 FT)

c) 2175 MM (7 FT)

d) 2375 MM (8 FT)

Width size is standard

Width size is standard : 900 MM

Depth available in

Depth available in : 300 MM

400 MM

450 MM

500 MM

600 MM

And all above depths have 5 Bin combinations in each.

Our shelving system, if considered at the time of project planning stage, not only gives more SKU’s in lesser area but also aesthetically looks good.